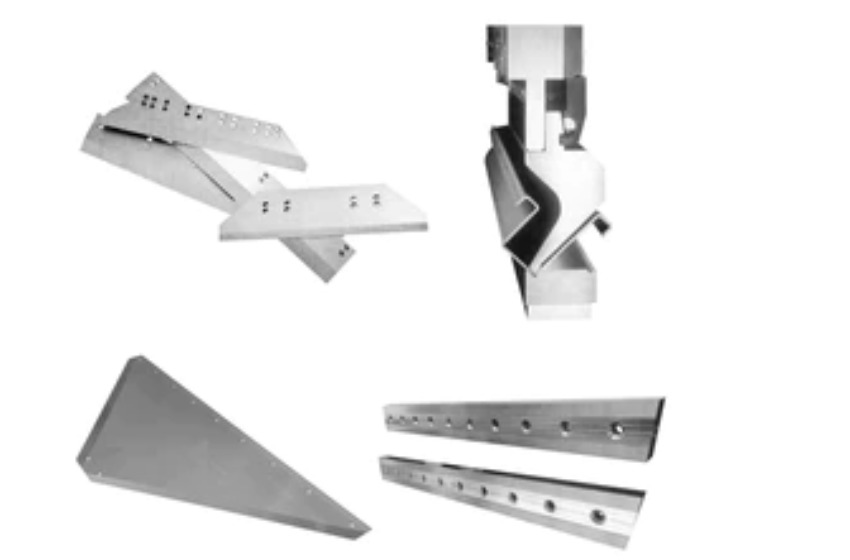

A guillotine knife manufacturer makes precision guillotine knives for a variety of industries. The blades are made from tool steel, stainless steel, high-speed steel, and sometimes tool carbide. They often include a tray sealer. In addition to standard guillotine knife designs, they also manufacture custom guillotine knives. In addition to offering standard guillotine knives, they also specialize in custom guillotine knives for industries that require precise guiding.

Guillotine Shears is a guillotine knife manufacturer

The cutting machine known as a guillotine shear is a powerful tool used in the fabrication of a variety of materials. Guillotine knives and shears have blade lengths up to six meters and are highly effective at cutting up to thirty millimeters thick sheets. Large shears are commonly designed with an upper blade that is not perfectly straight but tilted longitudinally. This design creates a scissor effect that reduces the amount of effort required for cutting and also indicates that blanking does not occur along the entire cutting line.

Guillotine shears are commonly used for cutting various materials. The guillotine knife manufacturer makes a range of models that can be used for a variety of industrial applications. These guillotine-type machines come in a range of sizes, from small table-mounted machines to bulky floor-standing installations. They are available here https://www.kangblade.com/ in hydraulic or mechanical designs.

Precision linear and parallel cutting

Precision linear and parallel cutting with a guillotine knife involves reducing the length of a mother sheet while maintaining the precision of the cutting line. The multi-objective genetic algorithm and binary representation of variables are employed to improve the cutting process. The Accura Easycut Guillotine Programming Device enables optimization of both guillotine and non-guillotine cutting.

After adjusting the height, angle, and force of the blade, the operator places the metal sheet on the horizontal worktable of the guillotine. A pressure beam is then activated to prevent the metal sheet from buckling. The main cutting process then begins. The guillotine knife moves downward with a uniform rectilinear velocity and halts on the upper surface of the worktable. After completing the cutting process, the guillotine moves back up to its starting position.

SECOND-CUT technology for thick or especially hard species of veneer

Veneers can be made from hardwoods ranging in thickness from 0.02″ to 2-1/2 mm, just a hair more than 3/32″. For this reason, thinner, more uniform slices are preferable. These are easier to slice, dry, and keep flat. Thicker species of wood, however, are much harder to work with. If you’re thinking about converting a piece of wood into veneer, consider SECOND-CUT technology.

Veneer-making technology developed in the war effort has helped to make furniture more durable. The development of better glues and machinery during the war helped manufacturers achieve a higher standard of quality in furniture manufacturing. The technology was quickly transferred to the veneer industry. Nowadays, it is the most popular choice for discerning interior designers. In order to create a stunning and elegant product, a thin veneer is used.