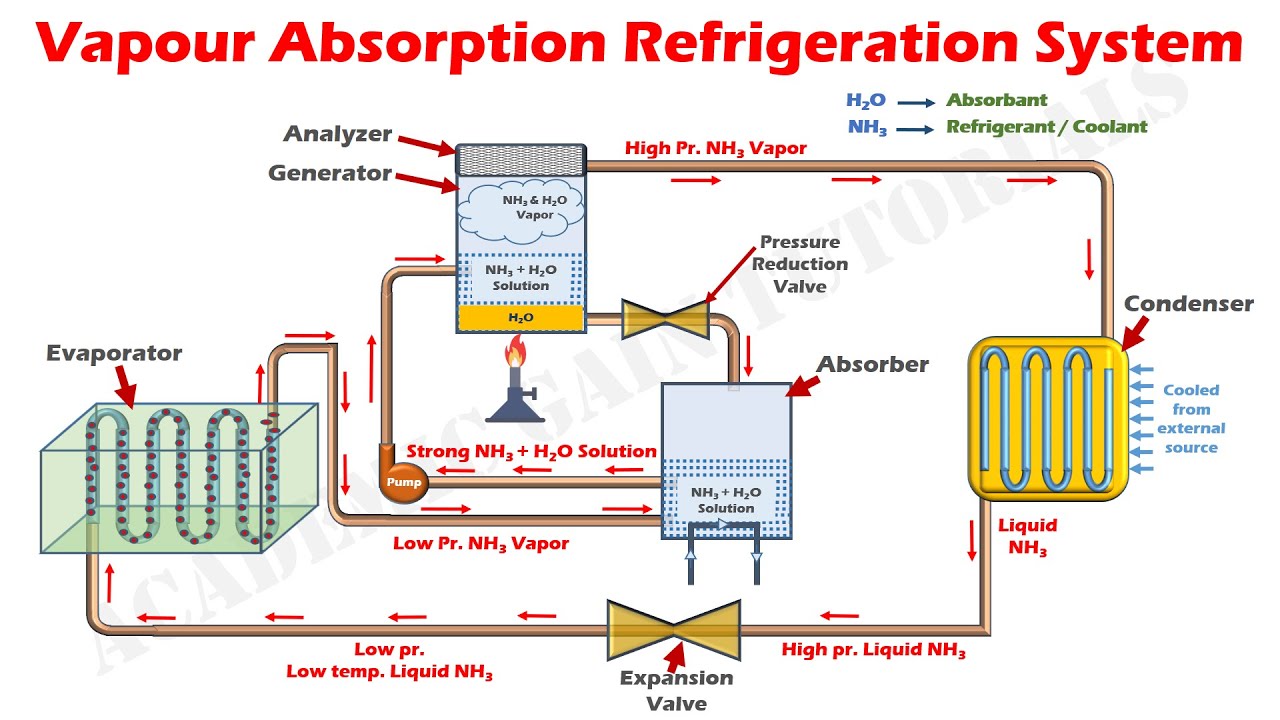

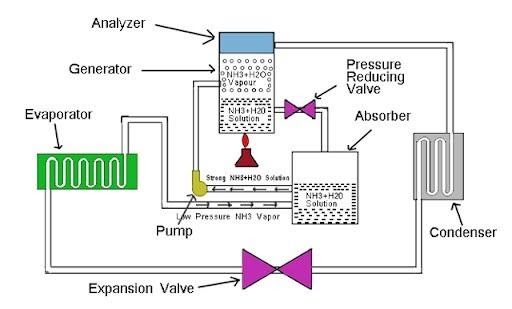

The working of the vapour absorption refrigeration system is very similar as the vapor compression system such as evaporation, condensation, expansion and compression. This system uses lithium bromide, water, or ammonia as a refrigerant.

In case of the vapour absorption refrigeration system, the refrigerant evaporates through evaporator and condenses through a condenser. The refrigerant creates cooling in the evaporator and releases heat to the surrounding via the condenser. It uses a generator and absorber in place of compressor.

The compressor can also wash out the refrigerant by the whole cycle. Therefore, the vapor absorption cycle uses a generator and an absorber.

This is why absorbers and generators are replacing compressors in absorption cycles. The absorbers allow the refrigerant to move as it is absorbed by the absorber into the generator.

Components in Vapour Absorption Refrigeration System

1) Expansion Valve

As the refrigerant flows through the expansion valve, its pressure and temperature drop sharply. After this process, the refrigerant (here ammonia) goes for the evaporation system.

2) Evaporator

Very low pressure and temperature refrigerant enters the evaporator and creates a cooling effect. In the vapor compression circuit, this refrigerant is drawn into the compressor, but in the vapour absorption refrigeration system, this refrigerant flows to the absorber as part of the suction of the refrigeration circuit.

3) Absorber

An absorber is a container that consists of water as an absorber and a previously absorbed refrigerant. The absorber therefore consists of a weak solution of the refrigerant (here ammonia) and the absorber (here water). As ammonia enters the absorber from the evaporator, it is absorbed by the absorber, further reducing the pressure in the absorber and increasing the amount of refrigerant flowing from the evaporator to the absorber.

At high temperatures, the water absorbs less ammonia, so it is cooled with an external refrigerant to increase its ammonia absorption capacity.

4) Pump

The pump draws a concentrated solution (rich in refrigerant) from the absorber and stores pressure and power in the generator. The strong NH3 solution in the generator is heated with gas or steam to drive off NH3 in the generator, heated with gas or steam to drive the NH3 vapor out to the condenser, and the weak solution is returned to the absorber.

After condensation in the condenser, the liquid NH3 under high pressure enters the evaporator through the throttle valve, absorbs the latent heat from the evaporator and generates cold heat.

5) Generator

Water and Ammonia mixture uses in the absorption system. Water uses as an absorbent and Ammonia use as a coolant and.

Water has a strong affinity for ammonia and forms two solutions. The absorber contains water and ammonia solution.

The generator provides supplementary heat by the external source. Supplementary units may use to deliver hot water, steam, heat, or any type of heating. Provides heat to transform aqueous and ammonia mixture into steam.

Advantages of Vapour Absorption System

- It has very low noise

- It has an easy control

- The vapor absorption system has low price

- It has long life cycle

- It doesn’t have refrigerant leakage issues.

Disadvantages of Absorption System

- These systems need costly pumps

- It has large size

- This system has very low COP