Within the industrial field, the oil and gas energy sector are one of the most relevant. The increase in technology usage in every industry gives rise to lubricant delivery software. Discover all the advantages of implementing software for the oil and gas industry to automate your production processes and improve management.

Software for the oil industry is a technological tool that facilitates and optimizes industrial processes, monitors product life cycle, and has absolute control of operations. Optimize resource management and your production with software for the oil and gas industry. This article discusses the correlation between dispatch software and lubricants’ route optimization.

What is software for the oil industry?

Oil and gas owners and suppliers need to automate most processes to work more efficiently and match Industry 4.0. New technologies are being introduced to improve productivity, optimize the supply chain and get the most out of all production phases, improving delivery times and the quality of services.

Machines and resources are crucial in implementing industrial software that optimizes, automates, and controls processes. Software for the oil and gas industry is an essential support in automating the operations of an oil or gas processing plant.

Features and functionalities of software for the oil industry

Manage business operations

A solution for oil and gas manufacturing and distribution companies allows centralizing information management and simply controlling all operations: monitoring the life cycle, production, or maintenance of facilities; and, in addition, make budgets for each project and evaluate possible risks, to reduce costs significantly.

Plan correction and forecast actions

Companies in the oil sector must identify, analyze and resolve incidents in the shortest time possible. With this tool, you will be able to carry out risk correction and prevention actions to anticipate any problem and find solutions more quickly, thanks to the real-time monitoring offered by the program and the automated warnings in the event of unforeseen events.

Manage the supply chain

A solution for the oil and gas sector guarantees maximum innovation and safety in the products and services offered. With it, you can track the supply chain of assets for more efficient production. Likewise, this tool allows monitoring earthworks and optimizing the management of the company’s resources flexibly.

Plan and manage projects

You can carry out project logistics planning, management, and execution with this tool. On the other hand, you will monitor their development and collect relevant data to facilitate decision-making.

Comply with current regulations

This system guarantees compliance with laws applicable to the oil sector, such as ISO 29001 (to guarantee product quality) or ISO 14001 (to reduce environmental impact).

Advantages of using software for the oil and gas industry

- Centralized financial control of all locations, with a global view of each plant’s production costs and performance

- Real-time recording of PLC data for perfect control of the entire production process and improved decision-making

- Adequate inventory and supply chain management, with automatic alerts and delivery time prediction

- Planning material needs (MRP) optimized and controlled the product’s entire life cycle, considering the clients’ deadlines.

- Manage the waste from the energy transformation process, considering the specific regulations for the sector and exhaustive documentary management of certificates

Route optimization – reduce costs & increase productivity.

Most supply chains are considered most costly at the last mile of their journey—many aspects to consider, including minimal, intractable, and usually impossible to standardize logistics. At the end of a supply chain, you are guaranteed to come up against customers that do not have a set of pre-determined requirements. This tendency makes operations more inefficient, and more flexibility is required to keep up with the times. Lubricant movements at the end of the supply chain are often modest and need many personnel resources.

Many businesses struggle to make efficient use of personnel and vehicle resources throughout the final mile of delivery. Fortunately, there are several solutions.

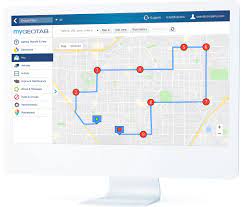

Route optimization has tremendous potential in various situations, notably the final mile. Consider the possibility of a more effective method to utilize your own and other resources. This may result in more efficient routes and higher production. It may be possible to cancel or shift trips with a negative contribution margin in some circumstances. These savings can range between 20% and 35%.

Every element of route optimization, from selecting the most appropriate tools to developing processes and a realistic, practical approach to realizing maximum potential, must be considered to get the best possible outcomes.

Conclusion

When optimizing routes, what needs to be considered is often overlooked in the wide range of options. These are:

- Clean data and processes

- Suitable software, trained employees

- Value-optimizing methodology and integration of related corporate divisions

The field of route optimization is still often underestimated today regarding the possible value contribution and the complexity to be solved.